This game-changing filling station employs our state-of-the-art control system centered around a 15-inch HMI touch screen interface, which allows the operator to manage the entire system from the single-point touch screen. UNICUS 4i™ has several innovative optional features including the BAUER Gas-Tek™ monitoring system and RFID Reader.

The UNICUS 4i™ all-in-one compressor system comes standards with Radio Frequency Identification (RFID) technology to scan cylinders quickly. This technology can be thought of as a next-generation bar code. A simple RFID Tag consists of a microchip and an antenna that transmit data back and forth. This process allows the user to quickly pull up critical information concerning their cylinders while in the station. Additionally, we offer BAUER Connect RFID collars for cylinders that are not already equipped with RFID tags. And, if the RFID tag breaks or is misplaced, a new RFID tag can be associated with cylinder while maintaining all of the historical information for that particular cylinder.

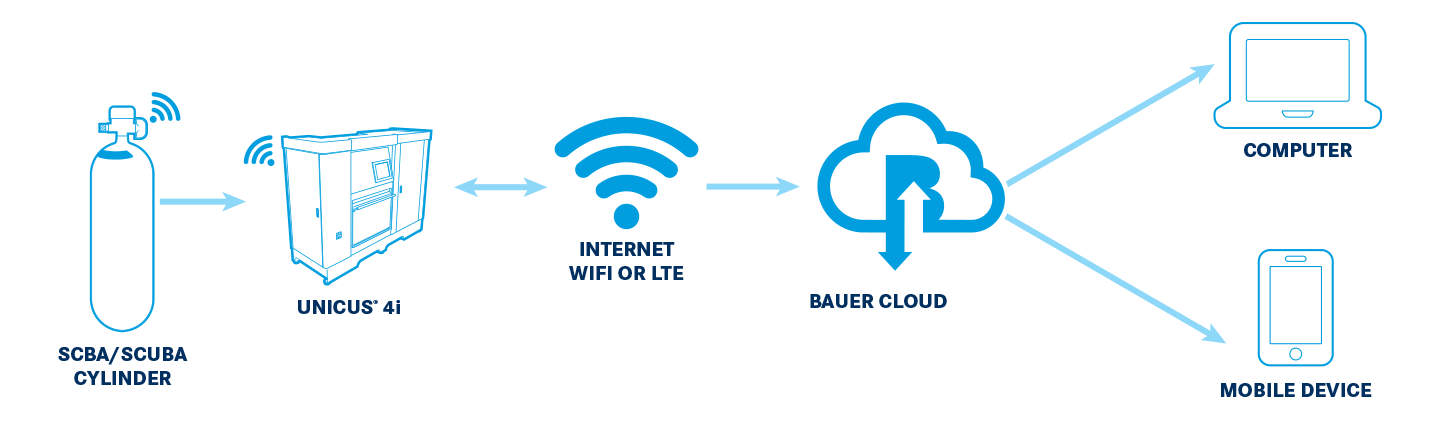

- Live connection to your Bauer Compressor system

- Monitor and control the unit

- Instant notifications of system issues/alerts

- Compressor runtime data

- Ability to monitor inner stage temperature and pressures

- Live connection to your Bauer Compressor system

- Monitor and control the unit

- Instant notifications of system issues/alerts

- Compressor runtime data

- Ability to monitor inner stage temperature and pressures

For over 70 years, BAUER has been the leader in high-pressure breathing air solutions for firefighting. When there is an opportunity to save time and create an even safer environment for your station, we take that very seriously. Introducing our new BAUER RFIDPro™ Self-Contained Breathing Apparatus (SCBA) / Self-Contained Underwater Breathing Apparatus (SCUBA) cylinder management system from BAUER allows fire departments to easily and conveniently stay in compliance with NFPA-1989 and OSHA regulations. BAUER RFIDPro™ helps increase the safety and productivity of fire department personnel while at the same time protecting municipalities and fire departments from liability exposure. The BAUER RFIDPro Self-Contained Breathing Apparatus (SCBA) / Self-Contained Underwater Breathing Apparatus (SCUBA) cylinder management system is a complete asset management tool that logs SCBA/SCUBA cylinder fills, keeps track of required hydrotests, cylinder repairs, and cylinder end-of-life expiration dates. The system is intuitive and easy to use: SCBA / SCUBA cylinders are scanned through the wireless BAUER RFIDPro™ reader, which automatically checks whether the cylinder is active (not previously tagged out or end of life) and whether the cylinder is current in regards to hydrotesting. If the cylinder is up to date, the system walks the operator through the cylinder inspection and fill process.

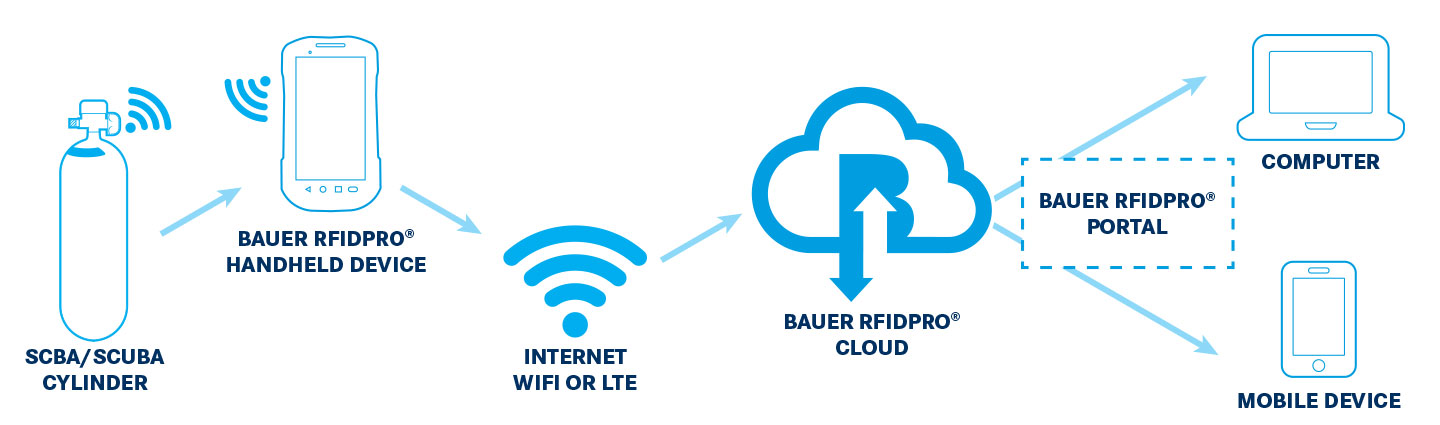

Our BAUER RFIDPro™ handheld mobile device utilizes Radio Frequency Identification (RFID) technology to scan equipment quickly. This technology can be thought of as a next-generation bar code. A simple RFID tag consists of a microchip and an antenna that transmit data back and forth. This process allows the user to quickly pull up critical information concerning their equipment while in the station or out in the field since we offer cellular handheld mobile devices. Additionally, we offer BAUER Connect RFID collars for cylinders that are not already equipped with RFID tags. And, if the RFID tag breaks or is misplaced, a new RFID tag can be associated with the cylinder while maintaining all of the historical information for that particular cylinder.

If your cylinders do not have RFID tags, and you do not wish to purchase BAUER CONNECT® RFID collars you can still use our BAUER RFIDPro™ handheld mobile device. Our devices allow the user to access all components of the mobile solution via a barcode scanner of the cylinder serial number or even manual entry of the serial number. Therefore, even if the barcode is scratched up, the user can manually enter the serial number in the mobile handheld device.

BAUER RFIDPro™ utilizes the power of cloud computing so that the data changes made on the BAUER RFIDPro™ handheld mobile device will instantly be reflected on this web portal. If you need to utilize the BAUER RFIDPro™ handheld mobile device in an area with no internet connection, it is no problem! The device will allow you to record changes offline, and as soon as an internet connection is available, it pushes the changes to the cloud. Our web portal also provides push notifications to you as equipment approaches critical dates. For example, suppose a Self-Contained Breathing Apparatus (SCBA) or Self-Contained Underwater Breathing Apparatus (SCUBA) cylinder needs hydrostatic testing soon. In that case, the customer will receive an automatic email reminder!

Easily add Self-Contained Breathing Apparatus (SCBA) / Self-Contained Underwater Breathing Apparatus (SCUBA) cylinders via the BAUER RFIDPro™ handheld mobile device or BAUER RFIDPro™ web portal. Critical National Fire Protection Association (NFPA) information concerning the cylinder history is recorded upon registration. These include Hydrostatic testing history and dates, cylinder expiration, and inspection questions. National Fire Protection Association (NFPA) inspection questions are included upon each fill. Additionally, the user can add their custom questions that they would like to track.

- Generates SCBA history reports including fill reports per NFPA 1989

- SCBA cylinder management and reporting is easily accessible through the user interface portal on the BAUER RFIDPro™ secure website

- The easy-to-use BAUER RFIDPro™ handheld reader can scan both RFID tags and bar codes

- Allows for customized department cylinder inspection in addition to the mandated NFPA cylinder inspection checklist

- Takes cylinder out of service if cylinder fails inspection, if the cylinder is overdue for hydrotesting or if the cylinder has reached its end-of-life

- Corrective actions such as cylinder repairs and hydrotests are documented through BAUER RFIDPro™ portal

- Tracks data for each fill event including date, who performed the fill, compressor and fill pressure

- The BAUER RFIDPro™ handheld reader can be operated offline when Wi-Fi connection is not available. Reader is available with LTE cellular option

- Handheld device allows for new cylinder registration

- Guest fill feature

- System allows for uploading of important documents such as hydrotests and repair certificates

- Instantaneous cloud synchronization of data

- Works on all SCBA manufacturers' RFID technology

- Ease of operation through intuitive design